3D-cutting technology of different cross section pipes

We offer proven robotic technology designed to automate plasma cutting of various sections.

This technology allows you to cut pipes complicated by 3D tracks, forming the front of the pipe according to the set configuration. Cutting quality allows the product to be delivered directly to the assembly site (welding site) without additional mechanical processing!

This technology also allows you to cut the required holes in the pipes. The swivel table in the complex provides an automatic position change, each of which provides controlled rotation of products during cutting. In order to obtain the best quality in a given complex, the option of automatic tracking of the cutting height is realized.The technology is realized as a Robotized Complex (ZТК), which provides cutting of pipes of various cross-sections and dimensions.

Features of a given technology:

- ZТК provides quality pipe cutting after any configuration;

- ZТК provides cutting holes in the pipe;

- The presence of a turntable provides a continuous production cycle, because on one position the operator performs the loading / unloading of the pipes, and on the other the machine performs a cut;

- The unique knowledge and capabilities of robotized plasma cutting allow to minimize the thermal impact on the front of the spring.

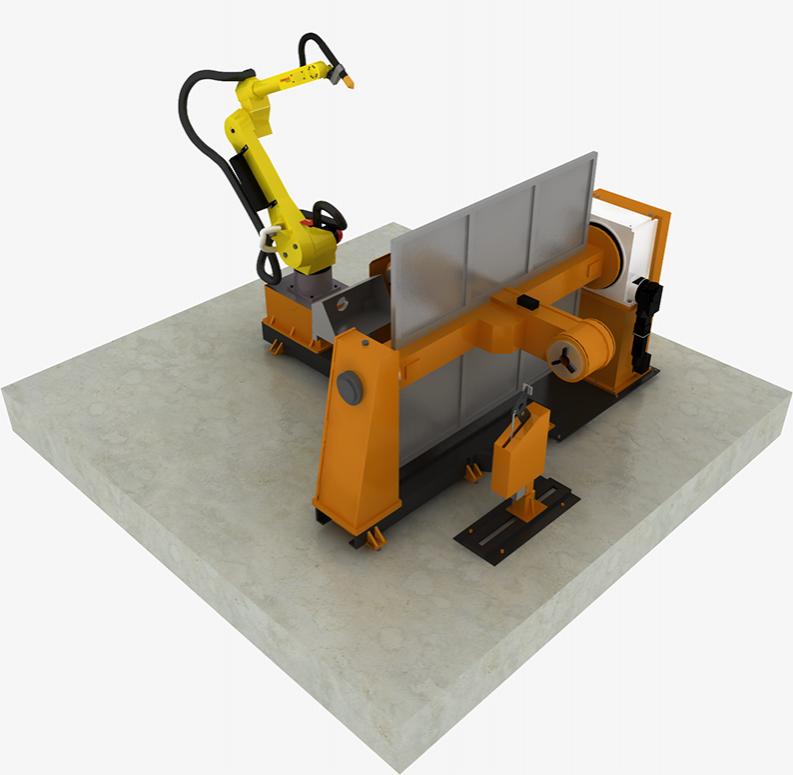

3D model of the complex:

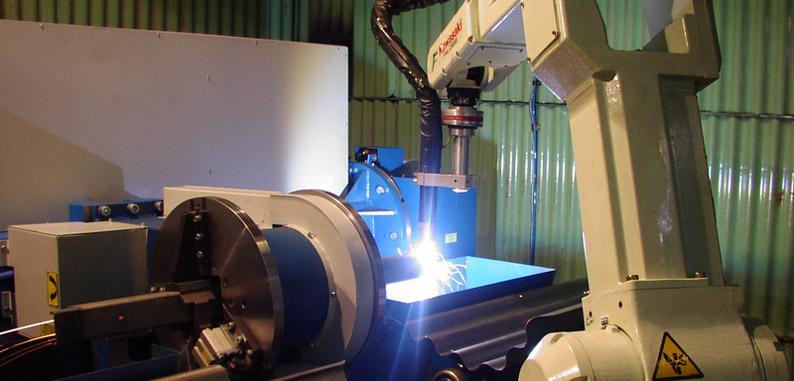

Photo and Video report:

\

US

US LT

LT LV

LV UA

UA PL

PL