3D Technology Cutting I-Beams

We offer proven robotic technology designed for the automation of volume 3D-cutting of beam beams of different dimensions.

This technology allows not only to cut (work on the face) of beams, but also to cut openings, including small holes, for subsequent assembly.

Technology is supplied complete with special software (own production). The software makes it easy to create complex cutting tracks and cut holes.

In order to obtain the best quality and adhere to cutting technology in a given complex, the option of automatic tracking of the cutting height is realized.

The technology is implemented as a Robotized Complex (ZТК), which ensures the cutting of beam beams up to 18 meters in length and metal thickness up to 36 mm.

Features of a given technology:

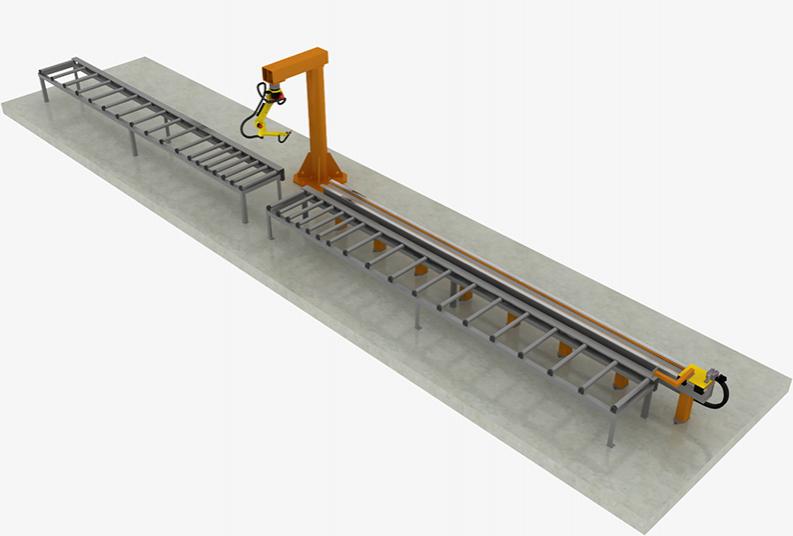

- The robot is placed on a Г-shaped column, which greatly extends its reachability;

- Special conveyor roller ensures the automatic feeding of beams in the cutting zone;

- Special measuring equipment is provided in the form of a backrest and is controlled by an additional axis of the robot.

- Unique software greatly simplifies the process of writing complex work programs.

Exterior appearance of the complex:

Automates the 3D cut of two-way beams on complex tracks, including:

- trimming the beams of a double beam;

- Cutting complex forms;

- cutting round and oval openings;

- Cutting openings;

- Cut figures: ellipses, rectangles, hexagons, octagons; Polygon of any form;

- Cutting walls and shelves at an angle of up to 45 degrees, cutting edge;

- groove cutting;

- making arches;

- Text marking, welding marking, hole punching.

The delivery kit includes its own software product (PP), which makes it possible to produce offline construction profile cutting / marking programs.

PP has a variety of cutting programs: straight face, alveoli, circular and oval holes, rectangular and arc shaped inlets, ellipses, rectangles, hexagons, octagons, polygons of any shape. In addition, there are special tools to easily program a complex cutting track with a tool orientation change. The PP contains commands for creating markings and signs for welding.After creating an offline cutting work program, the file moves to flash and then loads to the robot driver. The program can be started immediately and as a result, you get the finished part.

We will share your experience with you and we will educate your specialists. Our turnkey technologies are proven solutions that do not require detailed development at the design stage, reducing their overall cost.

US

US LT

LT LV

LV UA

UA PL

PL