Spot welding technology for elevator control panels

We offer proven robotic technology designed to automate spot welding processes for elevator control panels.

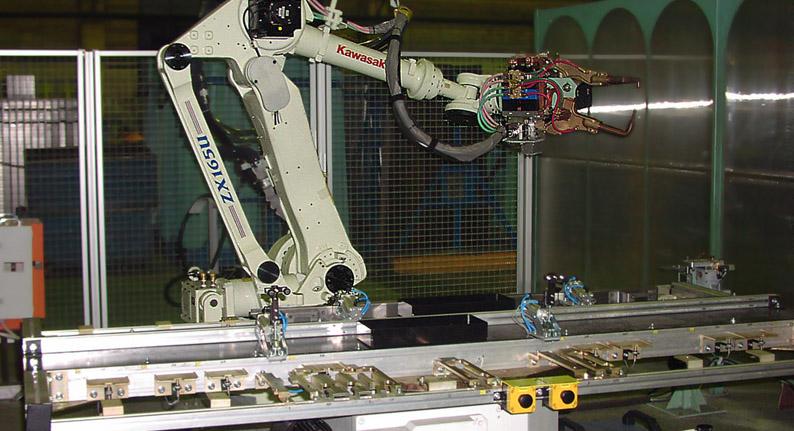

This technology provides spot welding of a variety of nomenclature of elevator control panels in a completely automatic mode. The turntable in the complex provides automatic position change, which ensures a 100% industrial robot load. The technology is realized as a Robotized Complex (RTC), which provides point welding for the wide nomenclature of elevator control panels.

Features of a given technology:

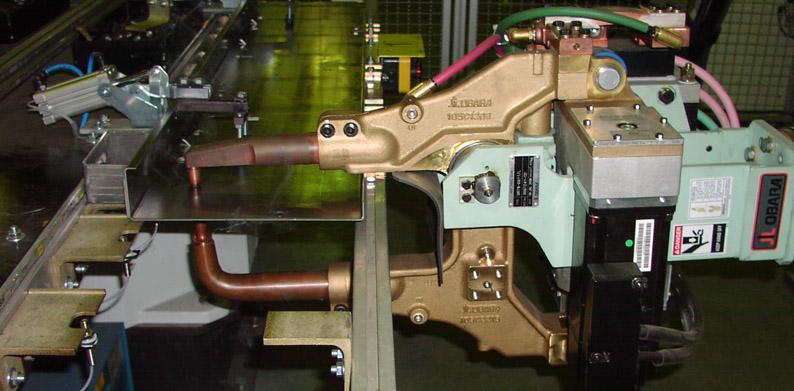

- RTC is equipped with servo-controlled Obara clamping pliers (Japan), which provides point welding with minimum thermal effect.

- The presence of a rotary table ensures continuous production cycle, because on one position the operator performs loading / unloading of the products, and on the other the robot performs welding.

- All-purpose technological tooling with pneumatic buttons assures the assembly of the various elevator control panel nomenclatures without previous graft welds.

Photo report:

Video report:

Our programmers have unique experience in programming and selecting welding parameters using state-of-the-art welding equipment and technology to achieve the highest quality and performance.

We will share your experience with you and we will educate your specialists. Our turnkey technologies are proven solutions that do not require detailed development at the design stage, reducing their overall cost.

For additional optimization of production costs, the contractor's participation in the project related to the manufacture of metal structures and equipment of the complex according to our drawings is also excluded.

US

US LT

LT LV

LV UA

UA PL

PL