Doors Welding Technology

We offer proven robotic technologies for automation of welding process during the fabrication of steel doors.

Each of the welding technologies we offer is delivered as a welding cell that ensures fully automated welding of the door leaves, frames and hinges without preliminary tack welds.

The process of welding cell implementation for doors welding includes three main steps:

1) Engineering and selection of the welding cell structure, including selection of the relevant equipment necessary to perform tasks relating to productivity.

2) Development and fabrication of process fixtures that ensure the assembly of door leaves, frames and hinges without preliminary tack welds.

3) Start-up and implementation of the welding cell, development of doors welding working programs, including selection of welding parameters that ensure optimal results.

1) Welding Cell Selection with Regard to Productivity Requirements

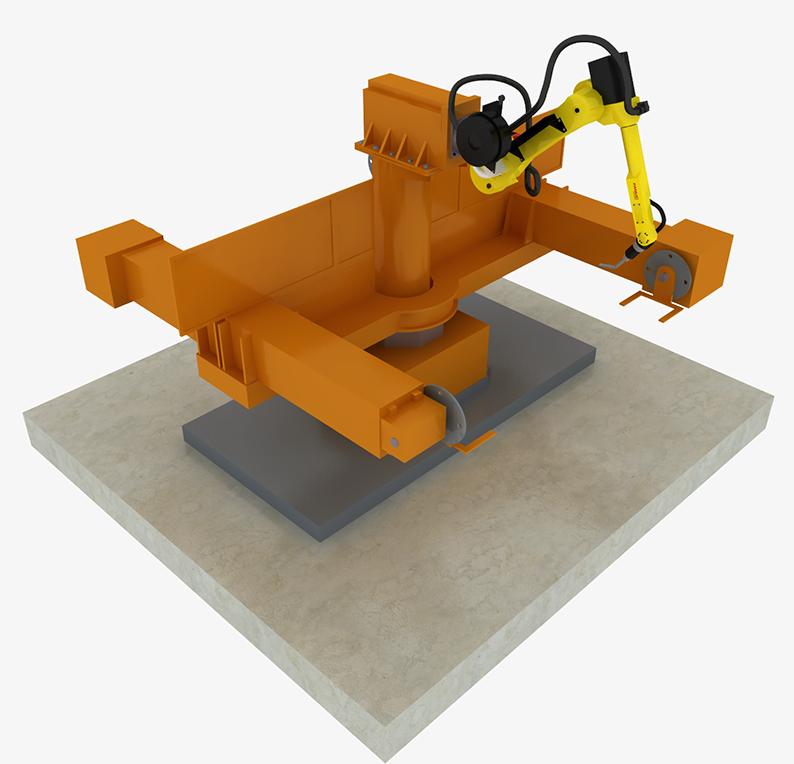

Option 1 (РТК-W101.10). Technology features:

- Productivity of РТК-W101.10 is 25 minutes - 1 set (door frame + hinges, door leaf + hinges).

- The positioner that is part of the welding cell serves as an additional robot axis and ensures controlled rotation of welded workpieces in horizontal plane.

- Chuck with a shift function to fix the position of workpieces having various dimensions; the maximal distance between the positioner surface plate and the chuck might vary depending on the customer requirements.

- L-column expands welding robot reach.

Welding Сell (Option 1):

Option 2 (РТК-W112.01). Technology features:

- Productivity of РТК-W112.01 is 15 minutes - 1 set (door frame + hinges, door leaf + hinges).

- Linear module expands welding robot reach and ensures its controlled shift.

- Two positioners ensure continuous welding cycle during which each positioner ensures controlled rotation of welded workpieces in horizontal plane.

- Chuck with a shift function to fix the position of workpieces having various dimensions; the maximal distance between the positioner surface plate and the chuck might vary depending on the customer requirements.

Welding Сell (Option 2):

Video report of a completed project:

Option 3 (РТК-W202.02). Technology features:

- Productivity of РТК-W202.02 is 9 minutes - 1 set (door frame + hinges, door leaf + hinges).

- Two welding robots increase overall productivity.

- Two positioners ensure continuous welding cycle during which each positioner ensures controlled rotation of welded workpieces in horizontal plane.

- Chuck with a shift function to fix the position of workpieces having various dimensions; the maximal distance between the positioner surface plate and the chuck might vary depending on the customer requirements.

Welding Сell (Option 3):

Option 4 (РТК-W301.01). Technology features:

- Productivity of РТК-W301.01 is 9 minutes - 1 set (door frame + hinges, door leaf + hinges).

- Industrial robotic arms ensure door hinges automatic feed to the weld area which is particularly useful in cases when the hinges design and, as a consequence, their position might change.

- Two welding robots increase overall productivity.

- The rotary table has two positions. One is used for welding, and the other - for the workpieces positioning, thus ensuring maximum robot load.

Welding Сell (Option 4):

Video report of a completed project:

2) Welding Fixtures Engineering and Fabrication

Engineering and design of welding fixtures is one of the most important steps since it has a great impact on the entire welding cell operation. The fixtures should not only fix firmly the position of a workpiece during the welding process, but also ensure welding burner access to the weld areas, including door hinges welding assembled without preliminary tack welds.

Belfingroup engineering department gained unique experience in the engineering and fabrication of process fixtures having any degree of complexity, including universal fixtures for preassembly of door frames and leaves of various dimensions.

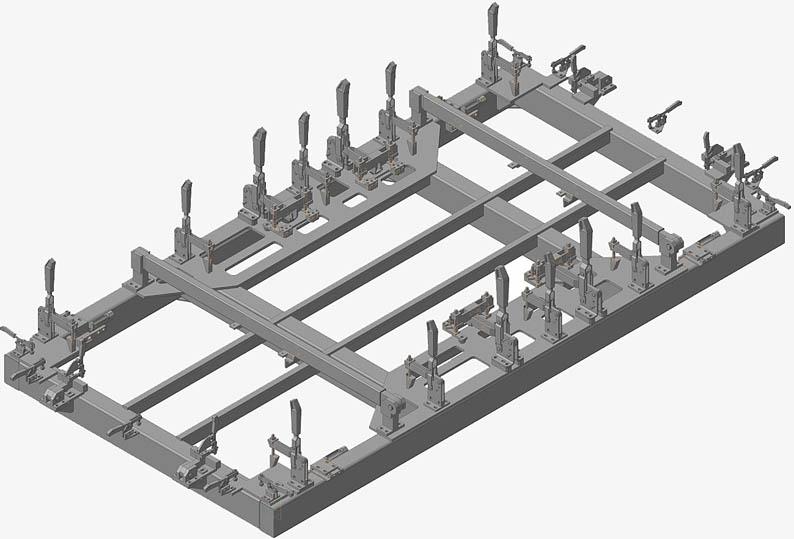

3d model of fixtures for the assembly of a door leaf without preliminary tack welds:

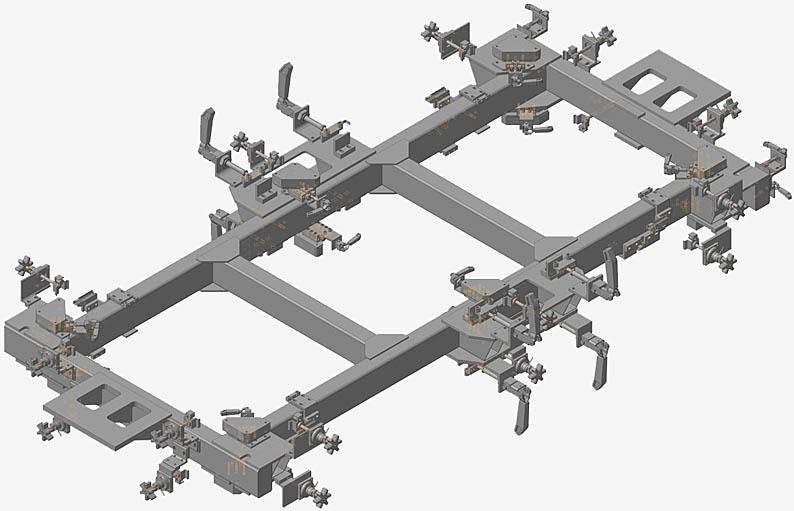

3d model of fixtures for the assembly of a door frame without preliminary tack welds:

3) Final step – Implementation of a Working Program for Automated Doors Welding

Welding cell practical implementation is a final and a crucial step which is possible only if all the previous steps have been successfully completed.

Our programmers have gained unique experience in programming and selection of welding parameters using the state-of-the-art welding equipment and technologies which ensure maximal quality and productivity.

We are ready to share our experience with you and to train your employees.

Our turnkey technologies are a proven solution that does not require additional detailed engineering during the design step, thus reducing the total price.

To further optimize production costs, customers are welcome to take supply steel structures and fixtures fabrication from our drawings.

Get a free consultation and quote by filling in the feedback form, or contact our sales department.

US

US LT

LT LV

LV UA

UA PL

PL